Historical

image

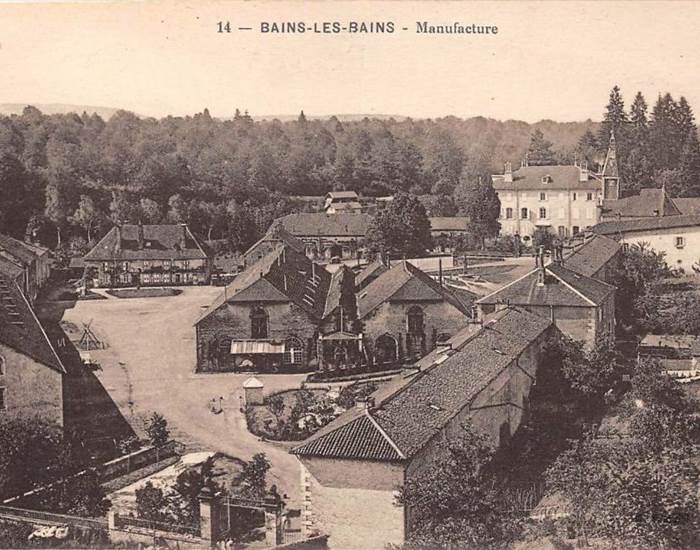

Founded in 1733 by authorization of the Duchess of Lorraine Élisabeth-Charlotte, the tinsmithing was entrusted to the care of Georges Puton (1679-1737), former grand alderman of Remiremont, who joined forces with Jean-Baptiste Villiez and the Coste brothers, Nancy merchants.

WHAT IS A TINWARE?

It is a place where tinplate, a mild tinned steel, that is to say covered with a thin layer of tin, is produced. Tin, very light, gives a ""white"" appearance to iron, as opposed to raw iron, which is almost black when it is not polished, hence the name tinplate.

The Bains-les-Bains tinsmith is located in the Côney valley, the river from which it draws its hydraulic energy. The surrounding forests provide it with the wood and coal necessary for its activities, particularly that of the forges.

All the work done on site is to transform iron ore blocks into tin plate with many steps.

The tinplate is then sold in France and abroad to make various household utensils (pans, lanterns, basins, etc.), tools and ship hulls. Due to their low production cost and their resistance to use (the tin layer prevents the iron from rusting), tinplate objects are very successful. They were only dethroned with the arrival of stainless steel at the end of the 19th century.

QUICK SUCCESS

Several buildings were built: the chapel in 1735, a tinning workshop in 1736 (which replaced that of 1733), a coal hall (1779, rebuilt in 1859), housing for workers and foremen, a castlecounting thirty-two rooms for the forge master (this is the title that Georges Puton then bore), but also a whole series of outbuildings as well as utility buildings such as an icehouse which made it possible, through its burial, to preserve winter ice For many months.

The majority of the buildings were completed before the death of Georges Puton. It must be said that the tinsmith industry is very prosperous. It is one of the few industries of its type in the region and, in 1764, almost 600 workers worked (and lived) on site. In 1777 the canal and the foundry were built.

During its development, the factory changed owners several times: Joseph-Antoine Vallet then the Falalieu family and finally the Chavane family who abandoned tinplate in favor of horse nails.It was in fact at the Manufacture Royale de Bains that the first industrial nail-making machines were manufactured (inventor: Charles Levy - 1851), which allowed a second era of prosperity.

In 1914, the nail factory became a clog factory before closing its doors definitively in 1951.

A NEW LIFE

The Manufacture could have fallen into ruin. This was without taking into account the courage of a descendant of the Chavane family who saved the place and obtained its classification as a Historic Monument. Since then, successive owners have decided to share this heritage with the public and bring it to life, notably with the renovation of homes and the creation of gîtes (currently around ten). The estate also hosts concerts, exhibitions and conferences.

Today Sophie and Frédéric are happy to welcome the many vacationers, spa guests or visitors who also enjoy a park with rare and remarkable species such as a twisted beech or fastigiated oaks...

An exceptional site therefore, and which has seen many famous people pass through. Thus, Julie Victoire Daubié, France's first high school graduate, was born there in 1824 (her father was a foreman of the factory) or Camille de Cavour, founder of Italian unity, who stayed there in 1824.

In recent years, the Manufacture Royale estate has also been highlighted by directors who use it as a film shooting location. After Indigènes and Now , the series Les Combattantes took advantage of this remarkable setting.